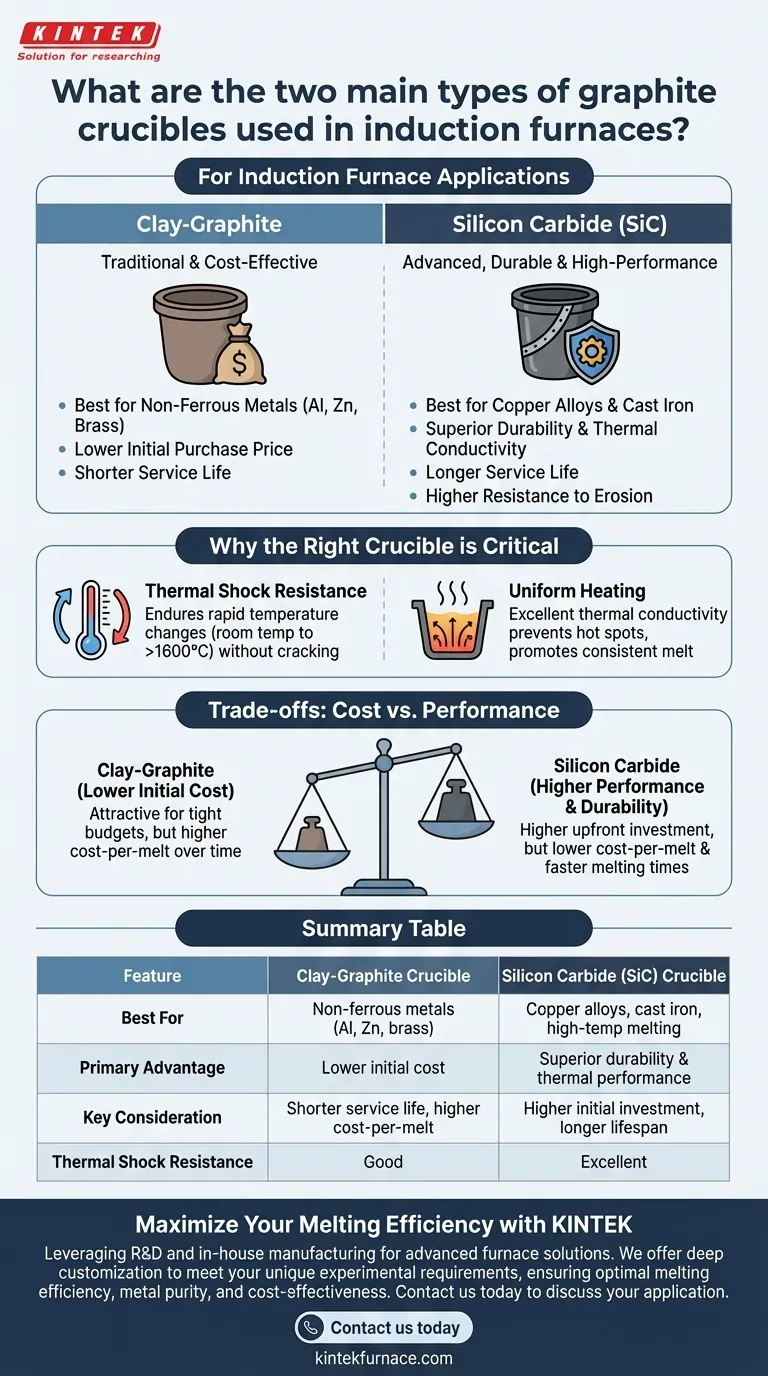

Für Anwendungen in Induktionsöfen sind die beiden wichtigsten Arten von Graphittiegeln Ton-Graphit und Siliziumkarbid-Graphit. Ton-Graphit-Tiegel sind eine traditionelle, kostengünstige Wahl, die durch das Binden von Graphitflocken mit Ton hergestellt wird, während Siliziumkarbid-Graphit-Tiegel ein fortschrittlicheres Verbundmaterial sind, das für überlegene Haltbarkeit und Leistung bei hohen Temperaturen bekannt ist. Die Auswahl zwischen ihnen hängt vom spezifischen zu schmelzenden Metall, der erforderlichen Betriebstemperatur und der gewünschten Lebensdauer ab.

Ihre Wahl des Tiegels ist nicht nur eine Materialauswahl; es ist eine kritische Betriebsentscheidung, die die Schmelzeffizienz, die Metallreinheit und die Gesamtkosten pro Schmelze direkt beeinflusst. Das Verständnis des grundlegenden Kompromisses zwischen den Anschaffungskosten eines Ton-Graphit-Tiegels und der Langzeitleistung eines Siliziumkarbid-Tiegels ist der Schlüssel.

Warum der richtige Tiegel entscheidend ist

Ein Tiegel für Induktionsöfen ist mehr als nur ein Behälter. Er muss extremen thermischen Schocks standhalten, chemischer Erosion durch geschmolzenes Metall widerstehen und Wärme effizient leiten, um eine gleichmäßige Schmelze zu gewährleisten.

Die Rolle der thermischen Schockbeständigkeit

Der Tiegel ist schnellen und extremen Temperaturwechseln ausgesetzt. Ein Material mit hoher thermischer Schockbeständigkeit kann diesem Zyklus von Raumtemperatur auf über 1600 °C (2900 °F) und zurück standhalten, ohne Risse zu bekommen, was die Betriebssicherheit und Langlebigkeit gewährleistet.

Die Bedeutung der gleichmäßigen Erwärmung

Graphitbasierte Materialien weisen eine ausgezeichnete Wärmeleitfähigkeit auf. Diese Eigenschaft stellt sicher, dass die durch das Induktionsfeld erzeugte Wärme gleichmäßig auf die Metallcharge verteilt wird, wodurch Hotspots verhindert und eine konsistente, qualitativ hochwertige Schmelze gefördert wird.

Ein detaillierter Blick auf die beiden Haupttypen

Obwohl beide Typen Graphit wegen seiner thermischen Eigenschaften verwenden, bestimmt ihre Zusammensetzung ihre idealen Anwendungsfälle.

Ton-Graphit-Tiegel

Dies ist der traditionelle Standard, der durch das Mischen von natürlichem Flammengraphit mit Bindemitteln wie Ton und Siliziumdioxid hergestellt und dann gebrannt wird, um eine keramische Bindung zu erzeugen.

Sie eignen sich am besten zum Schmelzen von Nichteisenmetallen bei niedrigeren Temperaturen, wie Aluminium, Messing und Zinklegierungen. Ihr Hauptvorteil ist ein niedrigerer Anschaffungspreis.

Siliziumkarbid (SiC) Tiegel

Diese fortschrittlichen Tiegel bestehen aus einem Verbundwerkstoff aus Siliziumkarbid und Graphit. Der Herstellungsprozess erzeugt ein außergewöhnlich dichtes und haltbares Material.

SiC-Tiegel bieten überlegene Festigkeit, ausgezeichnete Wärmeleitfähigkeit und eine höhere Erosionsbeständigkeit. Dies macht sie für eine breitere Palette von Metallen geeignet, einschließlich Kupferlegierungen und Gusseisen, und gewährleistet eine deutlich längere Lebensdauer als ihre Ton-Graphit-Pendants.

Die Kompromisse verstehen: Kosten vs. Leistung

Die Wahl eines Tiegels erfordert eine Abwägung zwischen der Anfangsinvestition und dem langfristigen Betriebswert.

Der Kostenfaktor

Ton-Graphit-Tiegel haben niedrigere Anschaffungskosten und sind daher eine attraktive Option für Betriebe mit knappen Budgets oder seltenen Schmelzplänen. Ihre kürzere Lebensdauer kann jedoch im Laufe der Zeit zu höheren Kosten pro Schmelze führen.

Der Leistungs- und Haltbarkeitsfaktor

Siliziumkarbid-Tiegel haben einen höheren Preis, bieten aber eine wesentlich längere Lebensdauer, oft viele Male mehr Zyklen als Ton-Graphit-Modelle unter ähnlichen Bedingungen. Ihre überlegene thermische Effizienz kann auch zu schnelleren Schmelzzeiten und geringerem Energieverbrauch führen.

Der Materialverträglichkeitsfaktor

Die chemische Beschaffenheit der zu schmelzenden Legierung ist von größter Bedeutung. Hochreaktive Metalle können Elemente aus dem Tiegel auslaugen, was zu Kontaminationen führt. Die robuste, dichte Struktur eines SiC-Tiegels bietet im Allgemeinen eine bessere Beständigkeit gegen diesen chemischen Angriff als eine Standard-Ton-Graphit-Version.

Die richtige Wahl für Ihre Anwendung treffen

Ihre Entscheidung sollte von Ihren spezifischen betrieblichen Zielen und Einschränkungen geleitet werden.

- Wenn Ihr Hauptaugenmerk auf dem Schmelzen von Nichteisenmetallen bei niedrigeren Temperaturen bei begrenztem Budget liegt: Ein Ton-Graphit-Tiegel ist oft der kostengünstigste Ausgangspunkt.

- Wenn Ihr Hauptaugenmerk auf dem Schmelzen bei hohen Temperaturen, der Maximierung der Ofenlaufzeit oder dem Erreichen der niedrigsten Kosten pro Schmelze liegt: Die Haltbarkeit und Leistung eines Siliziumkarbid-Tiegels bieten eine bessere Kapitalrendite.

Letztendlich ist die Auswahl des richtigen Tiegels eine strategische Entscheidung, die die Effizienz, Sicherheit und Qualität Ihrer Schmelzprozesse verbessert.

Zusammenfassungstabelle:

| Merkmal | Ton-Graphit-Tiegel | Siliziumkarbid (SiC) Tiegel |

|---|---|---|

| Am besten geeignet für | Nichteisenmetalle (Al, Zn, Messing) | Kupferlegierungen, Gusseisen, Hochtemperaturschmelzen |

| Hauptvorteil | Niedrigere Anschaffungskosten | Überlegene Haltbarkeit & thermische Leistung |

| Wichtige Überlegung | Kürzere Lebensdauer, höhere Kosten pro Schmelze | Höhere Anfangsinvestition, längere Lebensdauer |

| Thermische Schockbeständigkeit | Gut | Ausgezeichnet |

Maximieren Sie Ihre Schmelzeffizienz mit dem richtigen Tiegel

Die Wahl zwischen einem kostengünstigen Ton-Graphit-Tiegel und einem Hochleistungs-Siliziumkarbid-Modell ist entscheidend für die Produktivität und das Endergebnis Ihres Betriebs. KINTEK nutzt außergewöhnliche F&E und die Eigenfertigung, um verschiedenen Laboren fortschrittliche Hochtemperatur-Ofenlösungen anzubieten.

Unsere Produktlinie, einschließlich Muffel-, Rohr-, Drehrohrofen, Vakuum- und Atmosphärenöfen sowie CVD/PECVD-Systeme, wird durch unsere starke Fähigkeit zur Tiefenanpassung ergänzt. Wir können Ihnen helfen, die perfekte Tiegel-Lösung auszuwählen oder kundenspezifisch zu entwickeln, um Ihre einzigartigen experimentellen Anforderungen präzise zu erfüllen und optimale Schmelzeffizienz, Metallreinheit und Kosteneffizienz zu gewährleisten.

Kontaktieren Sie uns noch heute, um Ihre Anwendung zu besprechen und eine fachkundige Beratung zum idealen Tiegel für Ihre Bedürfnisse zu erhalten.

Visuelle Anleitung

Ähnliche Produkte

- Vakuum-Induktionsschmelzofen und Lichtbogenschmelzofen

- Thermische Heizelemente aus Siliziumkarbid SiC für Elektroöfen

- Labor-Quarz-Rohrofen RTP Heiz-Rohrofen

- Vakuumversiegelter, kontinuierlich arbeitender Drehrohrofen Drehrohrofen

- Hochtemperatur-Muffelofen für das Entbindern und Vorsintern im Labor

Andere fragen auch

- Was sind die Vorteile des Vakuuminduktionsschmelzens? Erzielen Sie überlegene Reinheit für Hochleistungslegierungen

- Was sind die Kernfunktionen des Hochvakuum-Induktionsschmelzofens (VIM)? Optimierung der DD5-Superlegierungsreinigung

- Wie funktioniert das Vakuuminduktionsschmelzen? Erreichen Sie ultrareine, hochleistungsfähige Legierungen

- Welche Rolle spielt ein Vakuuminduktionsschmelzofen bei Fe-5%Mn-C-Legierungen? Gewährleistung chemischer Integrität und hoher Reinheit

- Was sind die Hauptmerkmale und Vorteile eines Vakuum-Induktionsschmelzofens? Erreichen Sie die Produktion von hochreinen Metallen